Zero Point Clamping System

The ZeroClamp zero point clamping system is the modern alternative to the conventional T-slot table: Drastically reduces the setup times and increases your machine capacity.

Maximum user-friendliness

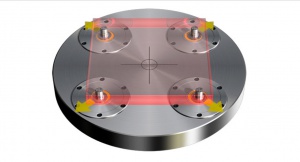

Highest degree of accuracy

Repeat accuracy of less than 2.5 μm.

Simple logistics

Just one type of clamping stud.

The key benefit

Thermal symmetry.

No tilting

Uncomplicated joining and removing.

One system for the entire process chain

Milling, turning, right up to quality assurance.

-90 %

Reduce setup times by up to 90%

+ 330 h

Additional production time per year

Save

29,700 euros per year

Assumption: 2 setup processes/shift; 2 shifts; 220 work days/year; machine-hour rate €90.00

Setup processes in comparison

Conventional setup process

1. Clean the machine table

2. Clean the clamping device contact surfaces

3. Position via the slot nuts

4. Align

5. Fasten with clamping screws

6. Determine the zero points

7. Start the program

8. End the program

.

Disadvantage:

It is difficult or even impossible to interrupt the process (completely remove the component from the machine table).

→ Machine standstill or workpiece is scrapped.

ZeroClamp setup process

1. Clean the machine table (reduced)

2. Clean the clamping device contact surfaces

Biggest time factor completely omitted!

3. Start the program

4. End the program

Benefit:

The process can be interrupted without a problem at any time.

→ Continued machine use.

Multiple benefits for day-to-day production work

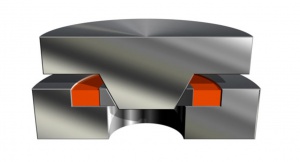

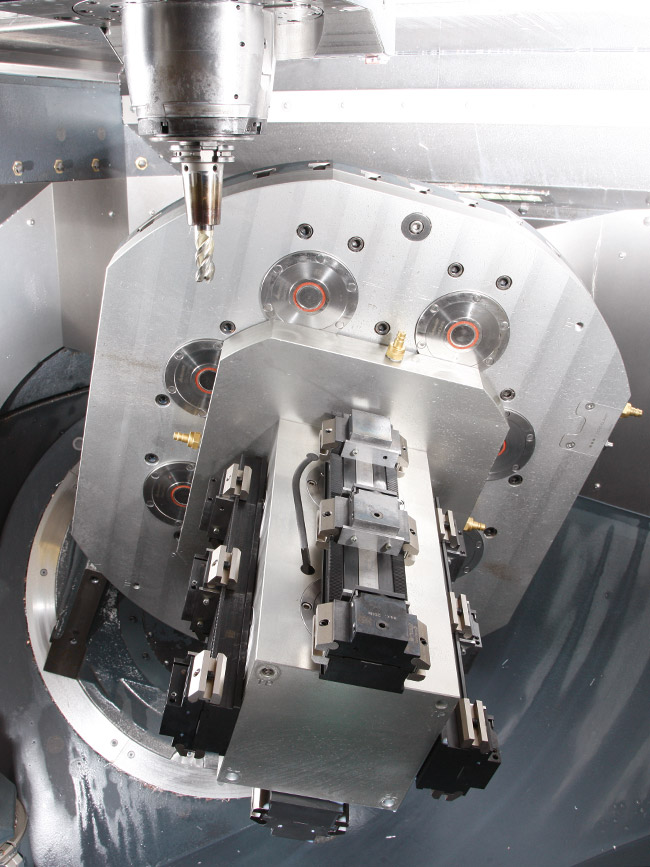

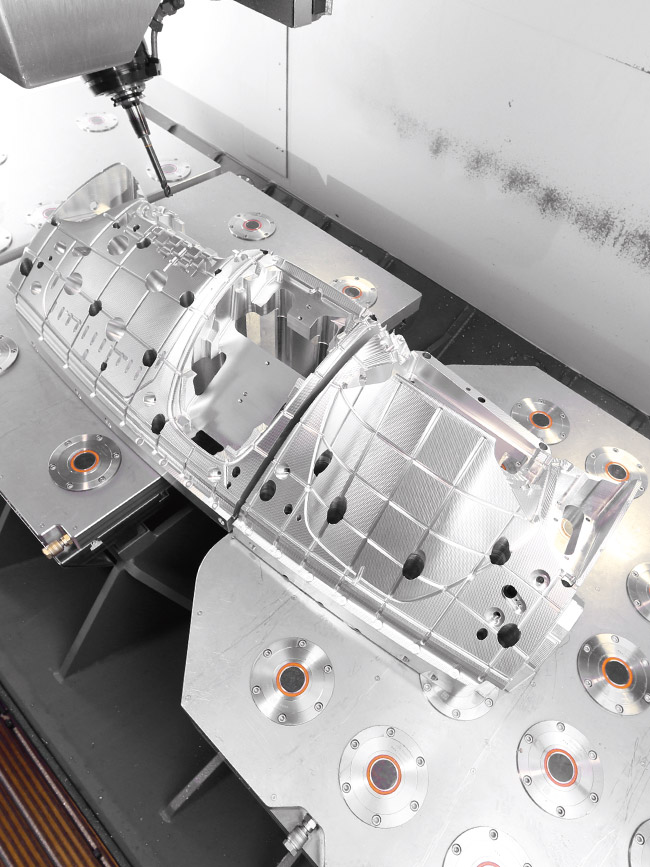

Milling

Direct clamping of the component onto a base unit. Holes as sockets for the clamping studs are specified at the design stage. Components can be changed quickly and accurately (across all machines).

Turning

In the case of turning operations as well, the productivity increases are used to best advantage with pre-balanced base units. Maximum safety with high forces thanks to additional retaining elements.

Spark erosion

Functions reliably even under water or in dielectric. The base units are equipped with special drain holes so that the water can escape when the pots are opened.

Quality assurance

There are also setup and non-productive times during measuring which can be reduced. Furthermore, the machining process can be interrupted for intermediate measurements on the measuring machine (the clamping studs are not removed for this purpose) before continuing with the process.

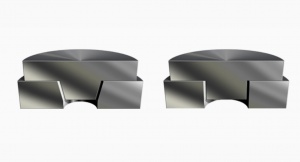

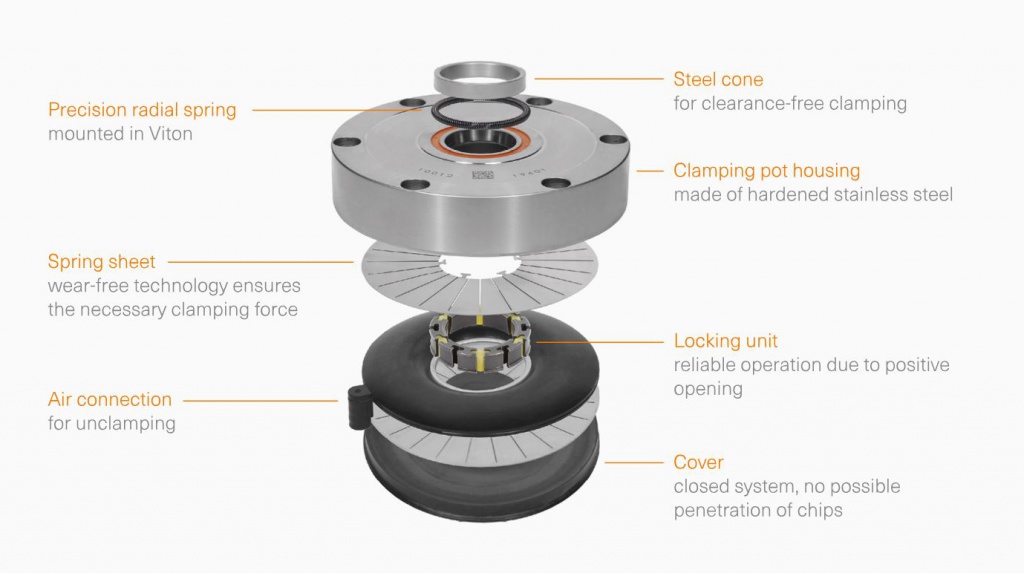

The center piece

Simple assembly with few components and very high repeat accuracy for at least one million cycles!

Pneumatic System:

Only 5.5 bar air pressure is required to release the clamping studs.

For comparison: classical systems

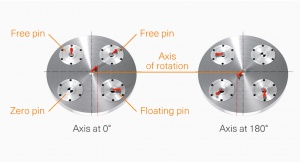

ZeroClamp thermal symmetry and accuracy

The ZeroClamp benefit

Easy to handle from a logistical point of view.

No differentiation between zero pins, floating pins, and free pinsJust one clamping stud type required!

Experience precision – system film

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Versatile clamping pots

From standard applications to automation

Clamping pots with a clamping force of 12.5 to 60 kN. Additional variants with position monitoring function and air coupling available for automated operation. All clamping pots are available with indexing holes (anti-twist device for single use).

Do you have questions about specific products or would you like some personal advice?

We are happy to help: Tel. + 49 8062 72948-0