Modular Clamping Rail System

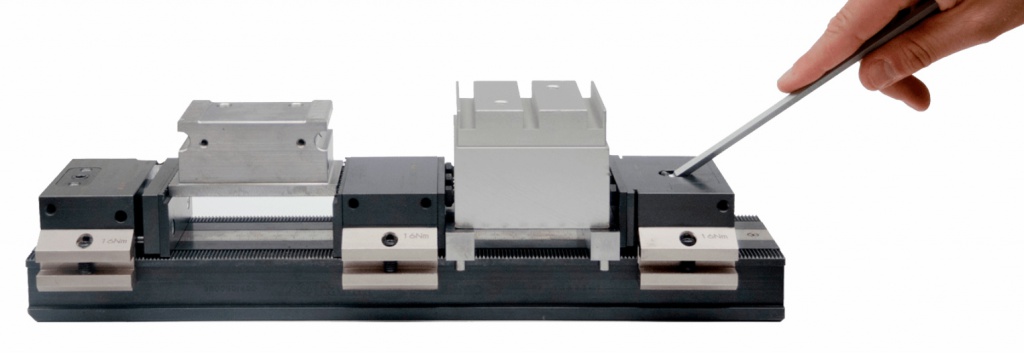

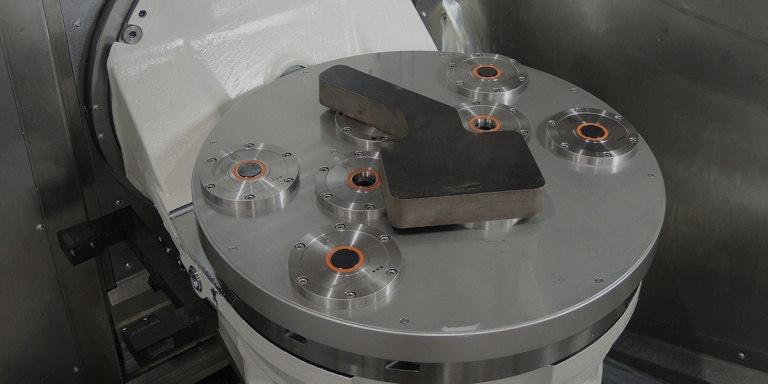

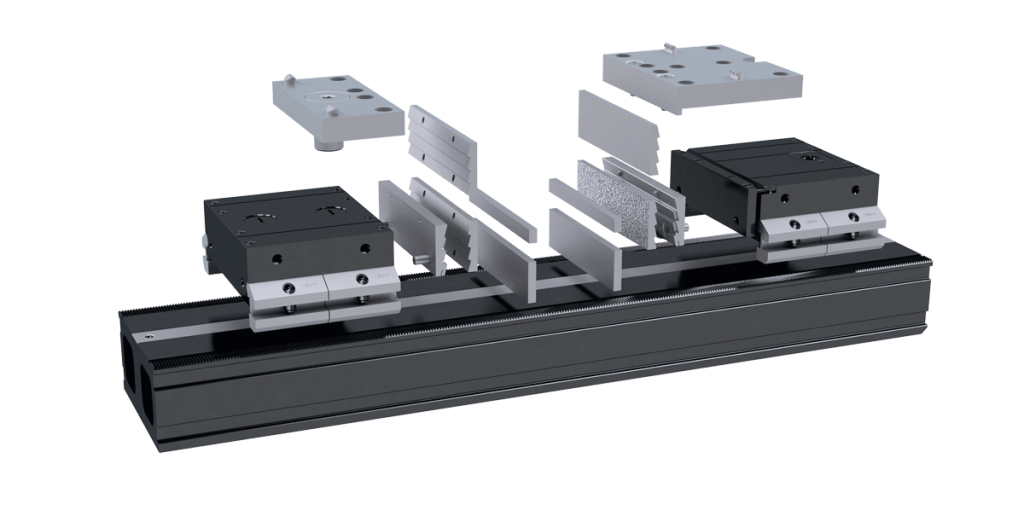

The two SL080 and SL120 modular clamping rail systems with a clamping force of 20 kN or 40 kN enable safe operation even in heavy-duty machining processes. All clamping widths possible thanks to clamping rails which can be coupled together infinitely.

ZeroClamp modular clamping rail system 80 and 120

Individual clamping widths

Suitable for both small and large workpieces thanks to clamping rails which can be coupled together infinitely.

Multiple clamping

Single and multiple clamping possibilities (flexible fixed jaws) in a 2 mm grid.

Unique clamping possibilities

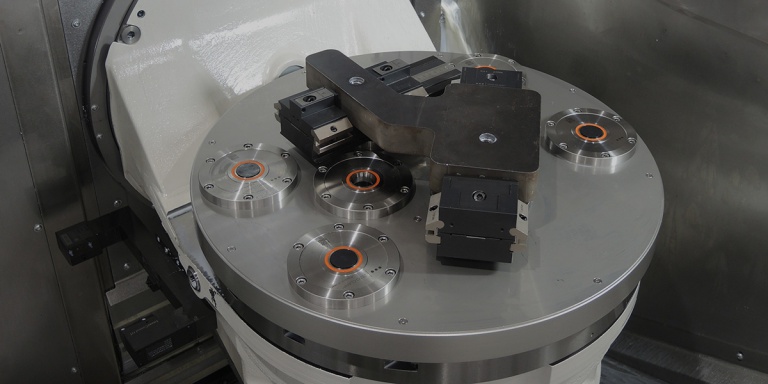

Clamping complex workpieces via rotating clamping rails (260 mm).

Modular design

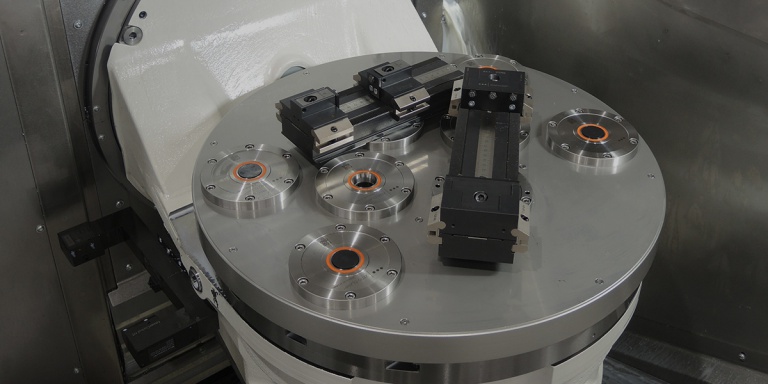

A large variety of clamping jaws and direct fitting on the zero point clamping system.

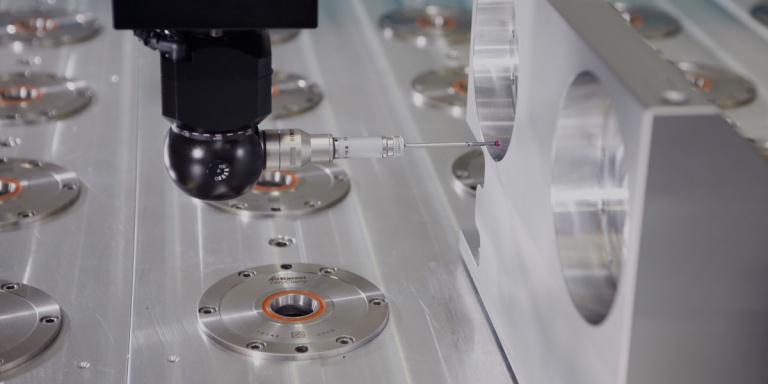

High pairing accuracy

0.03 mm

Clamping rails can be coupled together infinitely

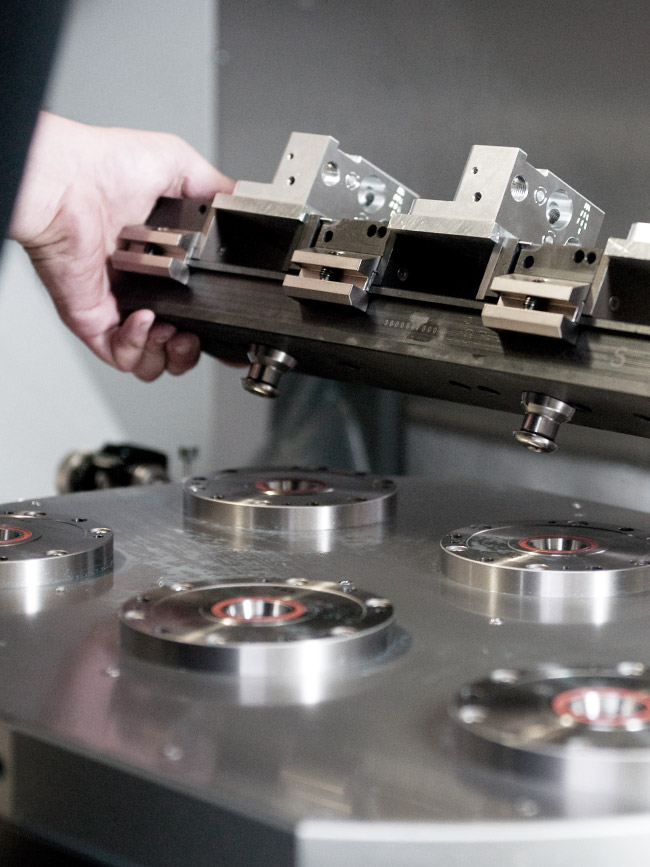

Lower height compared to conventional vices

– 50 %

Maximum utilization of the Z travel distance

Reduction in weight compared to conventional vices

– 70 %

User-friendly due to low weight

Multiple benefits for day-to-day production work

Flexible basis

All clamping rails can be fastened to the zero point clamping system by simply screwing in ZeroClamp® clamping studs. Using side clamps, the system can also be fastened directly to the machine table.

Blank part spanning

Reliable clamping of blank parts thanks to grip and toothed jaws.

Positive clamping

Positive clamping is enabled by pendulum jaws, but also by means of flexible rotating clamping rails with a length of 260 mm. Extremely bulky components (flame cuts or castings) can therefore be securely clamped and machined as a result.

Clamping multiple parts

Flexible clamping widths, even over several clamping rails, enable multiple clamping of different components. The reverse side of the clamping jaw is used as a fixed jaw for this purpose.

Centering clamping fixture

Centric clamping of blank and finished parts thanks to replaceable top jaws. Finished parts are ideally clamped with carbide-coated jaws or mold jaws.

The ZeroClamp process chain

ZeroClamp modular clamping system

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Comprehensive range of accessories

Enables you to clamp blank and finished parts and clamp accurately according to the contours of the part.

Do you have questions about specific products or would you like some personal advice?

We are happy to help: Tel. + 49 8062 72948-0